The common malfunctions of centrifugal blower and the methods of ridding them out

The common malfunctions of centrifugal blower and the methods of ridding them out

Jan 03, 2016

Centrifugal blower is a prime mover of the mechanical energy conversion to transport the gas, gas mechanical energy, in the smelting, chemical industry, sewage treatment and other fields plays an irreplaceable important role. In the actual operation, due to bad operating conditions, high failure rate, once the fault happened will lead to unplanned outages or reduced load operation, production cannot guarantee both quality and quantity, leading to serious production. So quick to judge of blower operation fault reason, to take effective measures to solve is a continuous safe operation of protection. Centrifugal blower fault types and different, reason is very complex, more is: bearing vibration, bearing temperature, fan surge.

This article is mainly about the bearing vibration and the corresponding solutions

1 centrifugal blower bearing vibration exceeded

Blower bearing vibration in the operation of the common fault, the vibration of the blower will bearing and leaf damage, loose bolts, chassis and air duct damage failure cause, a serious threat to the safe operation of the fan. Excessive vibration of the blower bearing many reasons, such as for different phenomena analysis the causes and take appropriate treatment measures, can often play a multiplier effect.

1.blade non working area ash caused fan vibration

This kind of defect is mainly manifested in the vibration of the blower in operation. This is because when the gas enters the impeller, with the rotating blade working surface exists a certain angle, according to the principle of fluid mechanics, gas in the non working face of a leaf must have create a vortex, so gas ash particle due to the action of the vortex will slowly deposited in the non working surface. Wing type blade is the most easily accumulated ash. When the dust reaches a certain weight due to the rotation of the impeller centrifugal force will be part of a large dust thrown out of the impeller. Because the leaves on the ash could not completely uniform, aggregation or can be thrown go grey blocks of time synchronization is not. Because the leaves of ash deposition uneven lead to imbalance in the distribution of the quality of the impeller, so that blower vibration increases.

This kind of defect is mainly manifested in the vibration of the blower in operation. This is because when the gas enters the impeller, with the rotating blade working surface exists a certain angle, according to the principle of fluid mechanics, gas in the non working face of a leaf must have create a vortex, so gas ash particle due to the action of the vortex will slowly deposited in the non working surface. Wing type blade is the most easily accumulated ash. When the dust reaches a certain weight due to the rotation of the impeller centrifugal force will be part of a large dust thrown out of the impeller. Because the leaves on the ash could not completely uniform, aggregation or can be thrown go grey blocks of time synchronization is not. Because the leaves of ash deposition uneven lead to imbalance in the distribution of the quality of the impeller, so that blower vibration increases.

In this case, it is usually only the leaves of ash to eradicate, impeller and a new equilibrium are reached, thereby reducing the vibration of the fan. In practical work, the air is more

Dirty, resulting in internal and external pressure is too large; the usual maintenance is also absolutely not sloppy. For example, the air quality requirements more stringent, and here we dust and more, so the workload of cleaning filter net is relatively large. It was once a month and a half, and we changed to a week, one time, greatly reduced the risk of clogging. In this case, we have taken some measures to improve the situation, the situation is greatly improved. At the same time also regularly clean up the cooling air filter, and strive to the blower is not a failure in this area. These measures have greatly improved the quality of the air, but it is not enough, we are considering to adopt a more effective and economical measures, completely solve the problem of air quality.

1.2 static and dynamic part of the collision caused by vibration of blower

(1) The unit of reyida exceed the standard deviation.

(1) The unit of reyida exceed the standard deviation.

(2) The rotor is not balanced in the process of installation and use.

(3) The rotor and the stator are in a standard deviation, there is friction and collision phenomenon.

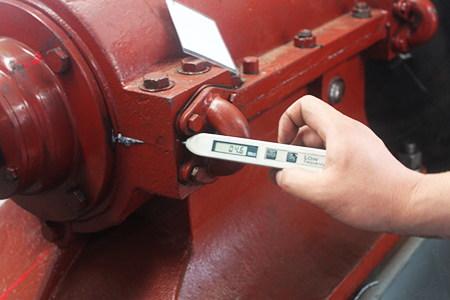

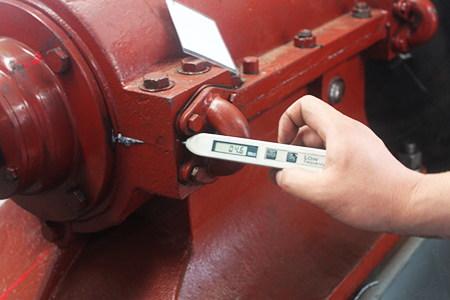

(4) The use of maintenance, bearing clearance, oil temperature and other parameters of the control.

1.3 corresponding solutions

(1) To check the rotor, each bearing adjustment unit, the unit in the rotor on the standard deviation requirements;

(1) To check the rotor, each bearing adjustment unit, the unit in the rotor on the standard deviation requirements;

Rotor has to consider the unit of work state under the influence of the temperature and the temperature rise of high bearing given leave a thermal expansion values and make the running status of the unit to reach the best state.

(2) In the repair process, must be carefully maintained, scientific maintenance, to prevent the destruction of the balance precision of rotor.

(3) The disintegration of the check of the rotor and stator are concentric, adjust the rotor or stator, the concentricity in line with the standard requirements, and avoid the phenomenon of friction or collision between stator and rotor.

(4) Reduce the bearing clearance and improve the temperature of lubricating oil; the bearing is in steady state operation.

This article is mainly about the bearing vibration and the corresponding solutions

1 centrifugal blower bearing vibration exceeded

Blower bearing vibration in the operation of the common fault, the vibration of the blower will bearing and leaf damage, loose bolts, chassis and air duct damage failure cause, a serious threat to the safe operation of the fan. Excessive vibration of the blower bearing many reasons, such as for different phenomena analysis the causes and take appropriate treatment measures, can often play a multiplier effect.

1.blade non working area ash caused fan vibration

In this case, it is usually only the leaves of ash to eradicate, impeller and a new equilibrium are reached, thereby reducing the vibration of the fan. In practical work, the air is more

Dirty, resulting in internal and external pressure is too large; the usual maintenance is also absolutely not sloppy. For example, the air quality requirements more stringent, and here we dust and more, so the workload of cleaning filter net is relatively large. It was once a month and a half, and we changed to a week, one time, greatly reduced the risk of clogging. In this case, we have taken some measures to improve the situation, the situation is greatly improved. At the same time also regularly clean up the cooling air filter, and strive to the blower is not a failure in this area. These measures have greatly improved the quality of the air, but it is not enough, we are considering to adopt a more effective and economical measures, completely solve the problem of air quality.

1.2 static and dynamic part of the collision caused by vibration of blower

(2) The rotor is not balanced in the process of installation and use.

(3) The rotor and the stator are in a standard deviation, there is friction and collision phenomenon.

(4) The use of maintenance, bearing clearance, oil temperature and other parameters of the control.

1.3 corresponding solutions

Rotor has to consider the unit of work state under the influence of the temperature and the temperature rise of high bearing given leave a thermal expansion values and make the running status of the unit to reach the best state.

(2) In the repair process, must be carefully maintained, scientific maintenance, to prevent the destruction of the balance precision of rotor.

(3) The disintegration of the check of the rotor and stator are concentric, adjust the rotor or stator, the concentricity in line with the standard requirements, and avoid the phenomenon of friction or collision between stator and rotor.

(4) Reduce the bearing clearance and improve the temperature of lubricating oil; the bearing is in steady state operation.

previous

Winter Solstice

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Sep 19, 2025

Possible problems in centrifugal fan selection?