One size does not fit all. In order to achieve high efficiency and high performance in fans, we customize the design according to the application.

Stress annealing furnace

(1) improves or eliminates various structural defects and residual stress caused by the casting or welding process of fan parts, and avoids deformation, cracking, etc. of the workpiece after operation.

(2) Refine the grains and improve the structure to improve the mechanical properties of the workpiece.

1000T double-arm hydraulic press

Used for the molding of impeller covers, air inlets, blades, and volute tongues to ensure the dimensional accuracy of important lines, thereby reducing the deviation between the actual operating performance of the fan and the theoretical design performance, and reducing the user's on-site operating costs.

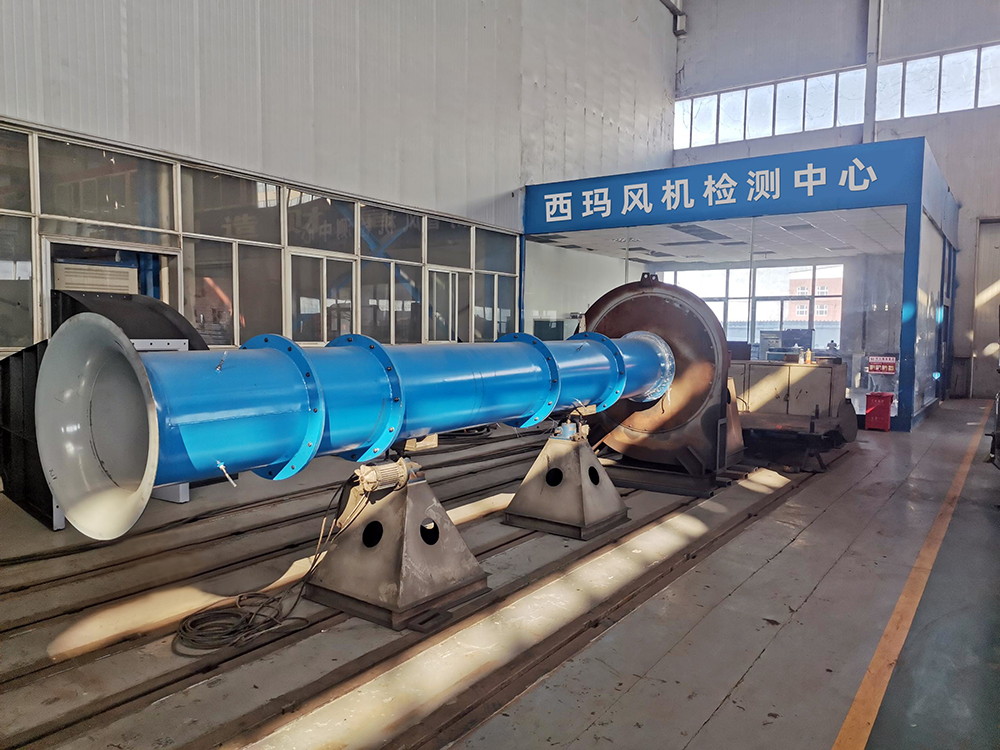

Fan aerodynamic performance test center

The wind turbine testing center is equipped with a full set of advanced testing equipment from the Shenyang Blower Research Institute, which can conduct performance testing, data analysis and energy efficiency evaluation of wind turbines. It is the only test method to verify whether the fan performance meets the standards.

Main Processing Equipment

SiMO Blower owns 69 vears of manufacturing experience, and masters advanced and mature fan manufacture technology.

We have complete set of production and testing equipments from raw materials to finished products.