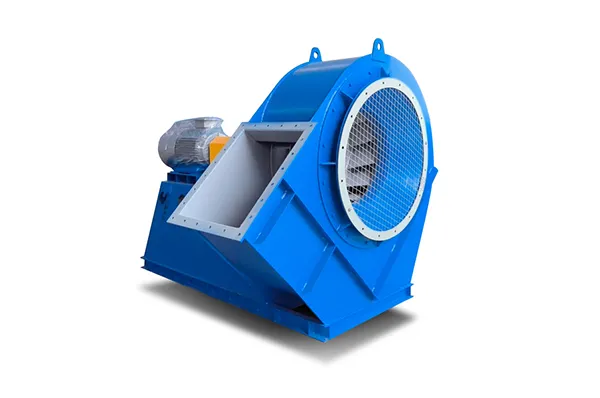

5-11 Series Centrifugal Fan/Induced Draft Fan

5-11 Series Centrifugal Fan/Induced Draft Fan

model:4#-30#

Rotation speed:≤4000rpm

Pressure range:684-9887Pa

Flow range:1199-435813m³/h

Gas temperature:0-250°C

If you can't find the datas you need, pls send us your performance requirements

we will provide you customized design service.

It is boiler induced draft fan with a total internal pressure efficiency of 90.5% specially designed to be suitable for various coal quality and equipped with a smoke-and-dust removal device (1~20 tons/hour).

This type of fan is currently used in the boiler industry. The air volume of the induced draft fan and the difference in wind pressure are relatively large, in order to adapt to the above situation, considering the practicability of the fan, in addition to the 20-ton boiler ID fan need large power coupling direct transmission, the other uses the triangular belt type transmission.

This can use different speeds to meet the requirements of various dust collectors in the same tonnage boiler, combined redundant fan series and machine number.

It is used to transport various common gases and hard materials in industrial production, and is suitable for various harsh conditions such as high temperature, wear and corrosion.

1.It is capable of outputting a higher outlet pressure while providing more gas flow with lower noise. Stable operation at higher media temperatures.

2.The adjustment door can be used to flexibly adjust the pressure and flow of the fan during operation. It can also be equipped with a variable frequency motor to adjust the pressure and flow of the fan by changing the speed.

3.The bearing cooling method selects a low-cost water-cooling method or an oil-cooling method with better heat dissipation depending on the gas temperature and the conditions of the use environment. For extremely high temperature operating conditions, an electronic cooler can also be added to absolutely protect the reliable operation of the fan system.

4.For the materials of impeller and main shaft, for different working conditions and working speed, we will choose high-strength carbon steel, low-alloy steel, high-temperature alloy steel, high temperature resistant high-strength alloy steel, make the impeller and main shaft to maintain reliable strength at high temperatures.

5.For dust-containing gas, we can meet various working conditions from a small amount of dust to a very large dust content. After special treatment, the surface hardness of the blade can reach HRC60~70, which can extend the life of the impeller by more than 3 times.

6.The bearing housing is reserved for temperature and vibration sensor mounting positions, for convenient to install the fan operation monitoring device.

7.The weld and the main shaft of the impeller are ultrasonic flaw detection to ensure that there are no welding defects and material defects to ensure strength.

8.After the production is completed, all products are tested for running and vibration values for reliable operation.

9.There are a variety of accessories to choose from.

|

Application |

Temperature |

Normal temperature air |

|

|

Hot air |

|||

|

Air composition |

Clean air |

||

|

Dusty air |

|||

|

Corrosive gas |

|||

|

Powder materials |

|||

|

Light particle materials |

|||

|

Performance |

Impeller diameter |

400-3300 |

mm |

|

Speed of main shaft |

≤4000 |

rpm |

|

|

Pressure range |

684-9887 |

Pa |

|

|

Flow range |

590.4-560735 |

m3/h |

|

|

Structure |

Blade |

Backward |

|

|

Impeller support |

SWSI (Single Width, Single Inlet), Impeller overhung. |

||

|

Drivetrain |

Coupling drivetrain |

Can assign |

|

|

Lubrication |

Oil bath lubrication |

Can assign |

|

|

Bearing cooling |

Air cooling or Circulating Water cooling |

||

|

System |

Motor |

SIEMENS, ABB, SIMO, LA… |

Can assign |

|

Impeller |

Carbon steel |

||

|

Impeller cone (Air Inlet) |

Carbon steel |

||

|

Case |

Carbon steel |

||

|

Air damper |

Carbon steel |

||

|

Main shaft |

High-strength carbon structural steel |

||

|

Bearing |

FAG, SKF, ZWZ, C&U… |

||

|

Bearing housing |

Cast iron |

|

|

|

Drivetrain |

Coupling |

Can assign |

|

|

Foundation bolt |

Carbon steel |

|

|

|

Optional |

System base frame, Protective screening, |

||

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)